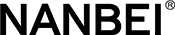

Automatic ion chromatograph

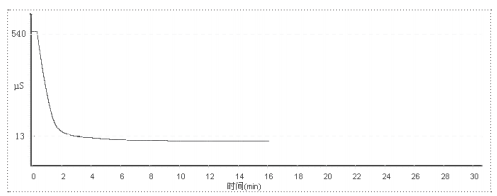

The electrochemical suppressor is specifically designed to be continuously self-regenerating.

Since the eluent has high background conductivity, chemical inhibition must be done so that signals from analytes can be detected. The inhibition of background conductivity is achieved through the reaction of CO32- and HCO3- in the eluent with H+ produced by electrolysis to generate H2CO3 of low conductivity during anion analysis and the reaction of H+ in the eluent with OH- produced by electrolysis to generate H2O.

H+ or OH- ions are produced by electrolysis without addition of extra eluent to realize automatic regeneration of ion exchange membrane.

Self-regenerative electrochemical suppressors for anions and cations are provided with the features of large inhibition capacity, low background conductivity (ppb level), low dead volume, rapid equilibrium, good repeatability, simple operation, easy maintenance etc.

• Full PEEK double plungers and low pulsation infusion pump with wide range of flow rates, stable operation and low maintenance costs.

• Full PEEK flow system for protection from metal pollution, high pressure, acids and alkalis and compatibility with organic solvents.

• High-speed data transmission and processing capabilities and automatic identification, control and real-time monitoring of the operating state of instrument components to ensure continuous and stable analysis.

• Advanced digital thermal conductivity detector with high sensitivity, high stability to ensure accurate and reliable results.

• Optional eluent generator to achieve automated eluent preparation.

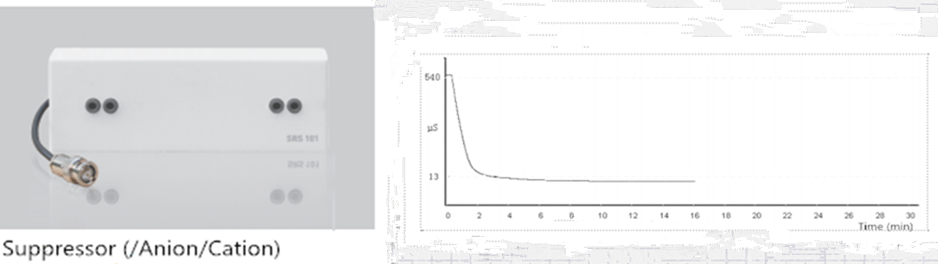

Advanced Software System

All instrument parameters are controlled through software and are displayed in the interface.

The Ace chromatography software is powerful and easy to understand. The instrument can also be operated through the front panel. The real-time status of each component can be monitored during the entire analysis process.

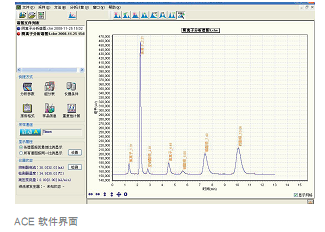

EG100 Eluent Generator - Ion Chromatography’s Helping Hand

Operators often need to change eluents of different concentrations and different types during analysis, which creates heavy workload and is inevitable to cause human errors. To solve this problem, Nanbei has launched a unique and automated EG100 eluent generator without an additional degassing unit.

• Scientific and reasonable structure design and no additional degassing unit to ensure reliable generation of eluent.

• Only one pump is needed to achieve concentration gradient elution.

• Both OH-, CO32- / HCO3- eluent for anion analysis and methanesulfonic acid eluent for cation analysis are generated automatically.

• Simple operation and control. Concentration of eluents can be set by software or though the front panel.

• High purity eluents are generated automatically without manual preparation to save operator’s time.

• Eliminate errors due to manual eluent preparation and long term storage to greatly improve the reproducibility of analysis results.

• Further reduce the background conductivity and noise and therefore improve the detection sensitivity.

• Reduce the time of the user’s exposure to chemical agents to create a safer working environment.

• Can be independently controlled via the front panel and used with any ion chromatograph.

DM-100/DM-101 On-line Degasser

Usages: DM-100 / DM-101 on-line degasser can be used for Nanbei-2800 series ion chromatograph, LC-5500 series high-performance liquid chromatograph, or ion chromatograph and liquid chromatograph from other manufacturers.

Features: On-line degasser has the features of high degassing efficiency, easy installation, fast baseline equilibrium, no drift, and low noise regardless of whether using isocratic elution or gradient elution.

Installation: DM-100 / DM-101 on-line degasser can be equipped with 1 to 4 degassing channels according to customer requirements. Either horizontal or vertical degasser orientation is selectable based on the overall structural design of the chromatography system being paired with. The on-line degasser can be installed between the reservoir tanks and infusion pumps.

| Analysis | |

| Detectable Ions | Anions: F-, Cl-, NO2-, Br-, BrO3-, NO3-, HPO42-, SO32-, S2O32-, SO42-, HCOO-, acetic acid, oxalic acid, outgrowth of sterilized tap-waterCations: Li+, Na+, NH4+, K+, Mg2+, Ca2+ |

| Detection Range | ppb |

| Dynamic Range | 103 |

| Linear Related |

0.9998 |

| Baseline Noise | ≤0.5%FS |

| Baseline Drifting | ±1.5% FS/30min |

| Fluid Pump | |

| Type | Parallel dual piston pump, pulse and motion controlled by microprocessor, speed adjustable. |

| Construction | Chemically inert, Non-metallic PEEK materials for the pump head and flow system |

| pH | 0-14 |

| Control | By Ace software or front panel |

| Operating Pressure | Max 35 MPa (5000 psi) |

| Flow Rate Range | 0.001~15.00 mL/min, 0.001 increments |

| Flow Precision | ≤0.1% RSD |

| Flow Accuracy | ±0.2% |

| Piston Valve Cleaning | Double piston continuous cleaning |

| Over Pressure Protection | Upper limit 0-35 MPa, with 1 unit incremental,lower limit: 1 unit lower than upper limit. Pump stops working if upper limit is reached |

| Online degassing (optional |

2-channels, automatic online |

| Temperature Controlled Conductivity Detector | |

| Type | Microprocessor controlled, digital signal |

| Cell Frequency | 10 kHz |

| Range of detection | 0-15000 µS |

| Resolution | 0.0275 nS/cm |

| Cell Temperature Range | Room temperature ~ 60℃, User adjustable |

| Temperature Stability | ≤0.005℃ |

| Cell Construction | PEEK |

| Cell Volume | < 1 µL |

| Column Oven | |

| Temperature Range | Room temperature + 5 ~ 60℃ |

| Temperature Accuracy | ±0.5℃ |

| Temperature Stability | ≤0.1℃ |

| Suppressor | |

| Suppression Type | Automated self-regeneration recirculation |

| Suppression Capacity | Anion 100 mmol/L NaOH |

| Cation 100 mmol/L MSA | |

| Dead Volume | < 50 |

| Equilibrium time | |

| Anion Suppressor Current | 0-200 mA |

| Cation Suppressor Current | 0-300 mA |

| Eluent Generator | |

| Eluent Concentration range | 0.1-50 mmol/L |

| Eluent Type | OH-, CO32-/HCO3-, MSA |

| Concentration Increment | 0.1 mmol/L |

| Flow Rate Range | 0.5-3.0 mL/min |

| Operating Temperature | Room temperature - 40℃ |

| Operating Humidity | 5% - 85% relative humidity, no-condensation |

| Dimensions |

586mm×300mm×171mm |

| Weight | 5 kg |

| Autosampler | |

| Sample Positions | 120 samples (1.8mL vials) |

| Repeatability | <0.3 RSD |

| Residue/Cross Contamination | CV<0.01% |

| Sample Volume | 0.1µL-100 µL |

| Injection Probe Cleaning | Repetitive cleaning, no time limit |

| Dimensions |

505mm×300mm×230mm |

| Power | 220±10V, 50/60Hz |

| Other Specifications | |

| Power | 220±10 V, 50/60 Hz |

| Environment Temperature | 5℃ |

| Environment Humidity | 5%-85% relative humidity, no-condensation |

| Communication Interface | RS485 (USB Optional) |

| Dimensions (length × width ×height) |

586mm×300mm×350mm |

| Weight | 34 kg |

| Power | 150 W |