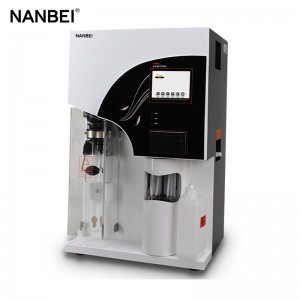

Automatic Kjeldahl Nitrogen analyzer

1. Using microcomputer to control the process

2. Automatically control the distillation, add water, control the water level, and cut off the water supply

3. Multiple safety protections: digestive system safety device, steam generator water shortage alarm, water level detection fault alarm

4. The instrument shell is made of special plastic-sprayed steel; the working area is made of ABS anti-corrosion board. Avoid chemical reagent corrosion and mechanical surface damage, acid and alkali resistance.

5. Once a fault is detected, the control system will automatically power off

6. Using tap water source, wide adaptability and low test requirements.

| Measuring varieties | Grain, feed, food, dairy products, drink, soil, medicine, precipitate, chemicals and so on |

| Working mode | Semi-automatic |

| Water-in mode | Tap water and distilled water

|

| Sample quantity | Solid: 0.20g-2.00g,

Semisolid: 2.00g-5.00g Liquid: 10.00ml-25.00ml

|

| Measuring range | 0.1mgN-200mgN (mg nitrogen)

|

| Recovery rate | ≥99% (relative error, including digestive process) |

| Distillation speed | 5-15 min/sample (according to sample amount) |

| Cooling water consumption | 3L/min

|

| Repetition rate | relative standard deviation <±1%

|

| Power | AV 220V/50Hz, 1000W

|

| Water supply | Water pressure >1.5MPa

Water temperature<20°C |

| Display | Digital |

| Temperature control | Digital control |

| Temperature range | Room temperature~600℃;

Accuracy ±1℃ |

| Temperature rising speed | 30℃/min |

|

Measuring range |

0.1mgN~200mgN |

| Test quantity | 4holes,8holes,12holes,20holes |

| Digestion time | 60~90 min/ group |

| Digestion tube capacity | 300ml |

| Power supply | 220(V)50Hz |

| Power | 4holes :1000w

8holes : 1500w 12holes : 2000w 20holes : 2500w |

Quartz infrared heating tube heating,mainly infrared,transfer is asistance;Fast heating,high efficiency.

The machine caseis made of special coating steel plate,work plate is made of stainless steel,have perfect corrosion resistance.

Double layers shell design,air thermal-protective coating and aluminium silicate thermal-protective coating,double thermal barrier effect. 4.Over-pressure,over-flow,over-heat etc multi protection.