Biological Fermenter

This system comprises 01 culture vessel with a total volume of 5L, pipelines, aeration system, sensor and instruments, local control system (based PLC and touch screen monitor), remote control system (including software and communications) and stainless steel bench etc.

MEASUREMENTS AND CONTROL System( Computer control system)

Industrial computer function:(without master computer)

The NB-7000 Biology process PLC and I/O channels. English operation menu. The displaying interface which is LCD used in big screen only can display 8 lines English words or tow analysis curves at the same time. The controller system is available to receive I/O signal from different sensors and actuators.

1. Control method:

1. Manual control: set the opening valve ratio.

2. Automatic control: choose PID continuum or PID on-off

3. Sequence control: set at least 10 steps of all control parameters beforehand to realize automatic subsection control.

4. Remote control: receive the master computer control

5. Associated control: DO control can be associated with rev, air flux, pressure and feeding. pH control can be associated with adding acid or alkali.

2. Computation function: measure the dosage of feeding, antifoam, acid and alkali.

3. x, y axis graph, which can spread or diminish images, helps the user judge the inter-influence of parameters, so as to modify or regulate the process of fermentation.

4. Data processing function:

a) Display and analyze the trend curves of all the parameters

b) Keep, display & analyze the 7,000 hours historic curves of the fermentation.

c) Display the report forms of fermentation of past 7,000 hours.

d) Deliver data to the master computer continuously or in batches, & copy data to floppy disks directly.

5. Control rev, temperature, pH, DO and foam height. Set upper and lower limit of rev, temperature, pH, DO and alarm if the parameters is out of the upper and lower limit. Alarm if the foam height is over the limit and add antifoam automatically.

6. Function of rectifying parameters: users can rectify, detect, control various parameters easily through menu as to control various fermentation of different scales

The self-protection of controller: users can set cipher to prevent others from changing the parameter of fermentation, moreover, the controller will not lose the set points of parameters caused by power off.

| 1) Vessel: | Total volume: 5L, working volume: 3.5L.

Special borosilicate glass vessel with flat stainless steel (316L) top-plate and bottom end. Autoclavable.

|

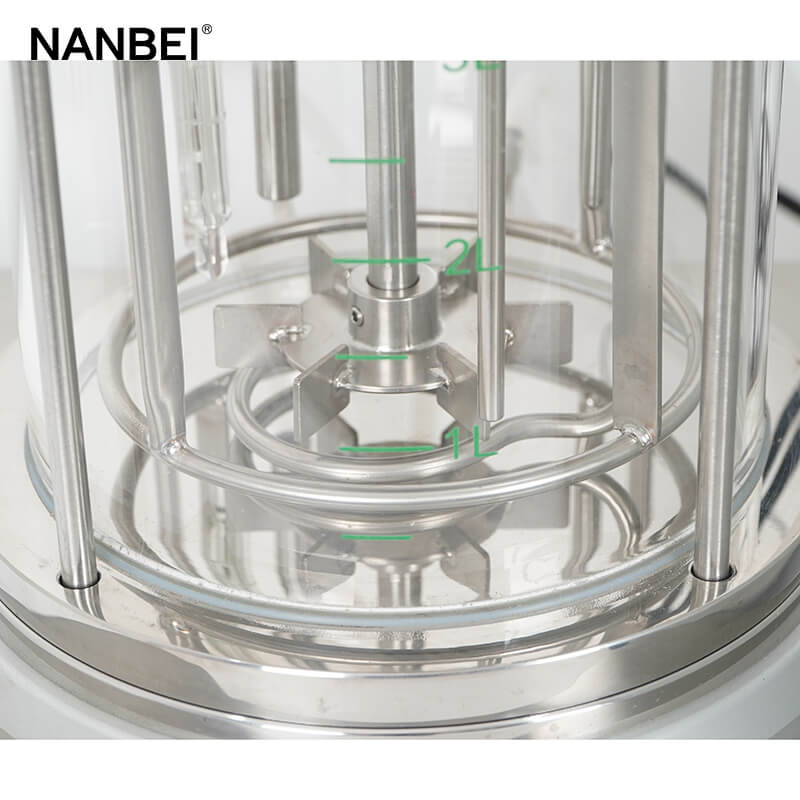

| 2) Top-plate: | Stainless steel (316L) top-plate, surface finished; with 2 septum addition ports, 1 flame inoculation port (also for harvest), 1 air inlet nozzle, 1 exhaust nozzle and 1 sampling tube etc. With 3 baffle cages and 1 “U” type cooling water tube. 1 Pt100 temperature sensor and 1 foam probe are provided. Clamp for silica gel hose at the side of the top-plate.

|

| 3) Drive: | With AC motor, speed adjustable. Magnetic drive from bottom. P=180W.

|

| 4) Agitator: | Solid stirrer shaft with 2 pieces of 6-blade disk impeller and 1 set of foam breaker. Rotate speed range: 50-1000rpm

|

| 5) Aeration: | With stainless steel ring sparger in the vessel and silica gel tube and PALL air filter outside.

|

| 6) Exhaust: | With stainless steel condenser and PALL filter. |

| 7) Peristaltic pumps: | 4 peristaltic pumps each assignable to function for acid/alkali, anti-foam and nutrient feeding. Each pump including perforation needles and silicone hose. Automatic or manual control.

|

| 8) Reagent bottles: | Two 250ml and two 500ml glass bottles with screw-on cap. Autoclavable.

|

| 9) Thermal circuit: | Electrical heating unit under the bottom end of vessel; piping and all required valves to be connected to cooling water supply.

|

| 10) Sterilization | Off-situ sterilization in the autoclave.

|

| 11) Power: | Main power supply for all electrical circuits, 220V/50Hz/1KW.

|

| 12) Control cabinet | Cabinet with beveled control panel. Accommodate all control loops ordered.

|

| 13) Bench: | Stainless steel (SS304) bench to support the glass vessel, surface polished. Accommodate motor and cooling water pipeline. |

| 1) pH | § Sensor: Gel filled pH electrode (steam sterilizable)

§ Indication: Digital display § Range: 2.0~12.0 § Precision: 0.01 for measuring, 0.1 for controlling § Control: PI control for injecting acid or alkali via regulating 2 peristaltic pumps. Automatic alarm

|

| 2) DO | § Sensor: Dissolved oxygen electrode (steam sterilizable)

§ Indication: Digital display § Range: 0%-100 % or 0%-200% § Control: online detected only

|

| 3) Temp. | § Sensor: Sterilizable PT100 probe

§ Heater: Electric heating unit. § Range: 5oC above cooling water to 40oC for controlling, and 0 to 150oC for measuring § Precision: +/-0.3oC § Indication: Digital display § Control: PI control. Automatic alarm

|

| 4) Agitation | § Drive: DC motor, Magnetic drive from bottom

§ Range: 50-1000rpm § Precision: +/-3 rpm § Indication: Digital display § Impeller: 2 pieces of 6-blades disk impeller § Control: PI control. Automatic alarm

|

| 5) Pressure | § Indication: pressure gauge

§ Control: manual

|

| 6) Aeration | § Flow Meter: Glass rotameter

§ Inlet Filter: 0.2um PALL filter, sterilizable § Control: Manual

|

| 7) Feeding | § Indication: Injecting dosage cumulating and digital display

§ Control: Set-point control via regulating a peristaltic pump.

|

| 8) Anti-foam | § Probe: Sterilizable conductivity probe

§ Indication: Injecting dosage cumulating and digital display § Control: Electronic control of pumping via conductivity control. Automatic alarm |