Double Layer Jacketed Glass Reactor - 50L double layer jacketed glass reactor – NANBEI

Double Layer Jacketed Glass Reactor - 50L double layer jacketed glass reactor – NANBEI Detail:

Working Principle

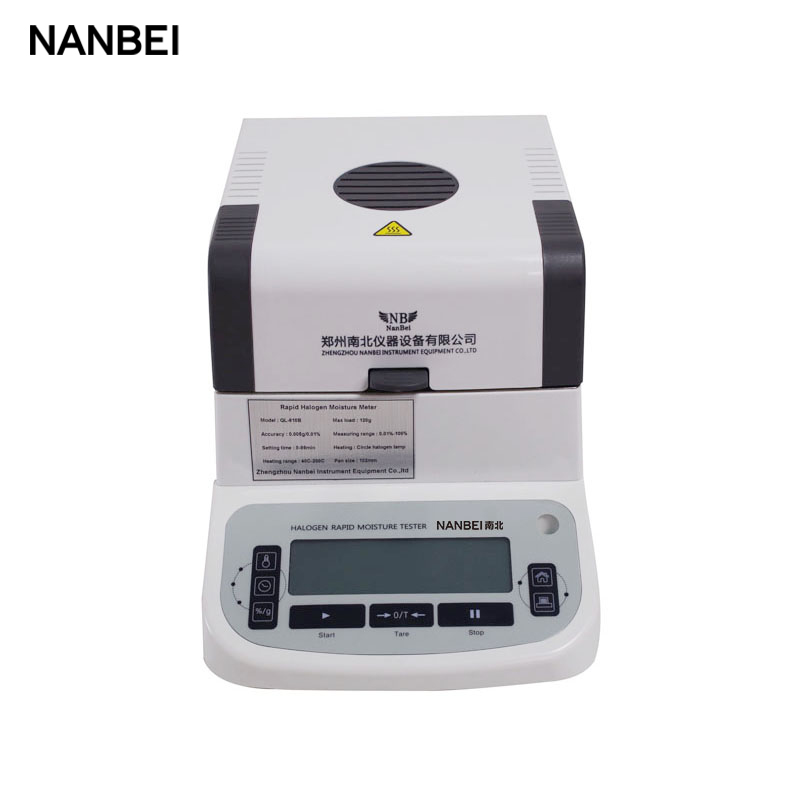

Through the interlayer of the double-layer glass reactor, a constant temperature (high or low temperature) hot solution or cooling liquid is injected to heat or cool the materials in the reactor at a constant temperature, and can provide stirring. The materials are reacted in the glass reaction kettle, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the materials can be discharged from the discharge port at the bottom of the kettle, and the operation is extremely convenient. It is an ideal equipment for modern chemistry primary and middle school experiments, petrochemicals, medium-scale experiments, biopharmaceuticals and new material synthesis. The pharmaceutical reaction process is clear at a glance, and it is convenient to control the reaction process.

Features

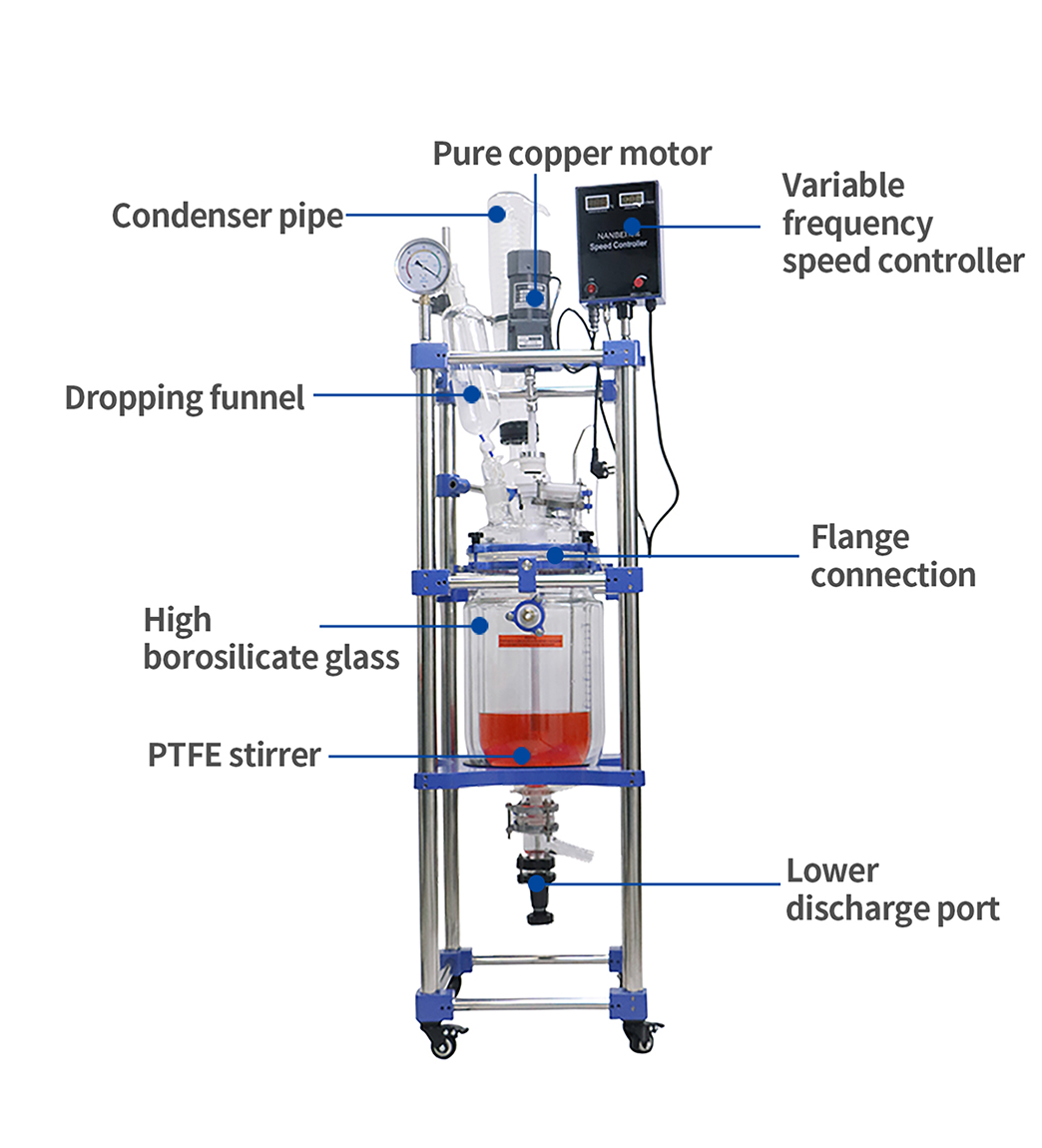

1. A full set of glassware with GG3.3 borosilicate glass production with good chemical and physical properties

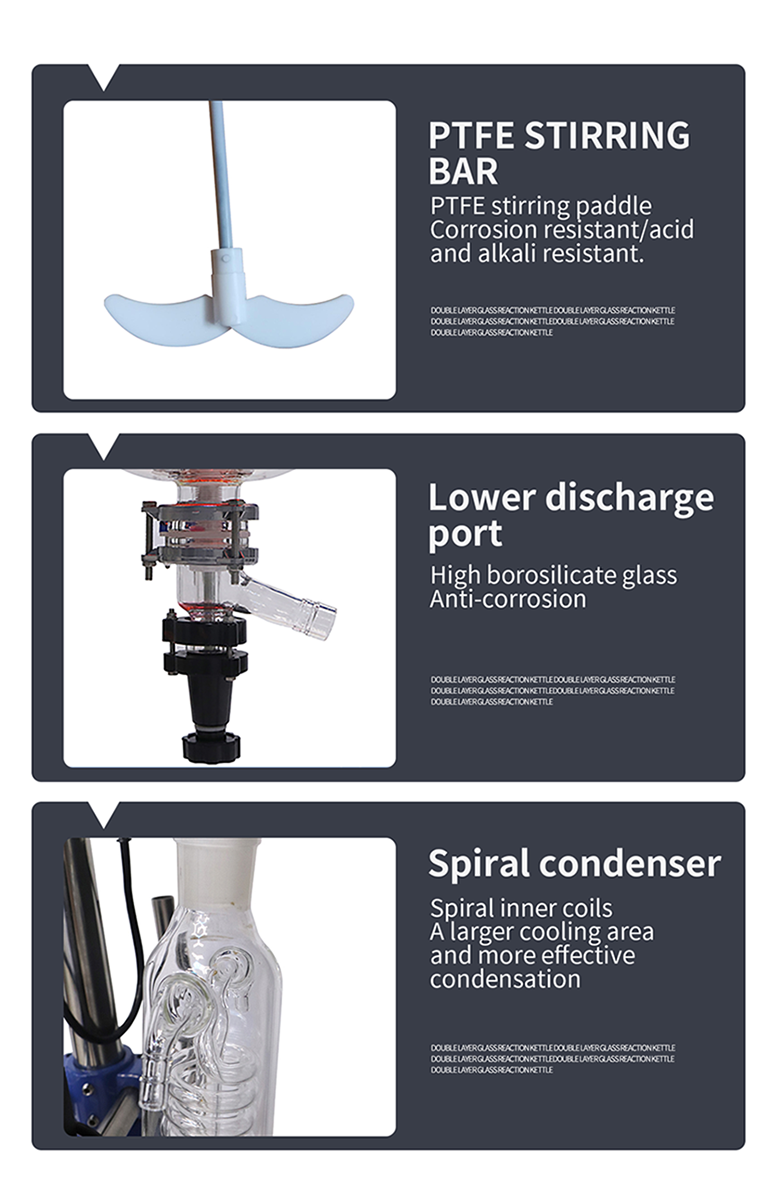

2. Limit temperature of 250°C for high temperature experiments, and limit temperature of -60°C for low temperature experiments.

3. Titanium ring, new titanium alloy mechanical seal, sealing 0.098Mpa.

4. The PT100 temperature, and is a liquid crystal display. More accurate temperature measurement and more convenient.

5. Frequency control, AC induction motor. Constant speed, brushless, no spark, security and stability, and continuous work.

6. Quality 304 stainless steel all-inclusive PTFE stirring rod and a three-bladed propeller structure.

7. The bottom flanged discharge port with a Teflon value, aluminum parts flange fixed container no dead ends.

Product parameter

| Model | NB-50L |

| Glass Material | GG-17 |

| Frame Material | 304 Stainless steel |

| Fittings Material | 304 Stainless steel |

| Moves | Brake Caster |

| Reaction bottle capacity | 50L |

| Jacketed Capacity | 12L |

| Flanged out of the oil circulation port | Low feed high outlet |

| Reaction bottle cover | Six port |

| Discharger port distance to ground | 450mm |

| Temp. range | -80-250℃ |

| Vacuum degreee | 0.098Mpa |

| Stirring speed | 0-450rpm |

| Stirring diameter | 12mm |

| Stirring power | 120W1/3 |

| Coltage(V/Hz) | 220V/50Hz |

| Dimension(mm) | 760*560*2450 |

| Packing size(mm) | 1720*680*850 |

| Packign weight(KG) | 92 |

Product Specification

Product Details

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for Double Layer Jacketed Glass Reactor - 50L double layer jacketed glass reactor – NANBEI , The product will supply to all over the world, such as: Zurich, Plymouth, Austria, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.