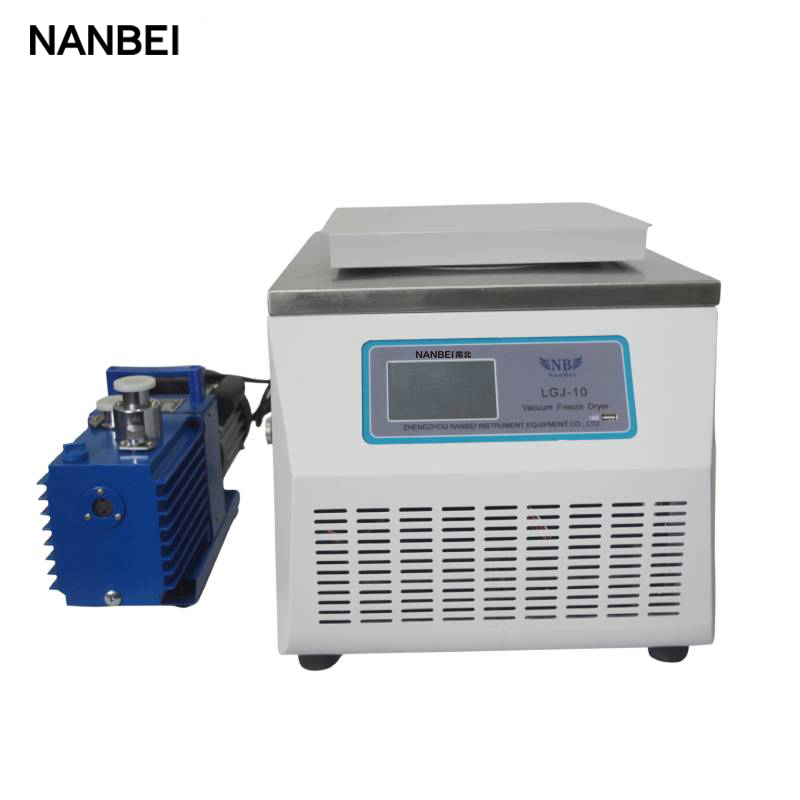

Laboratory Freeze Dryer – 1L Laboratory Freeze Dryer – NANBEI

Laboratory Freeze Dryer – 1L Laboratory Freeze Dryer – NANBEI Detail:

Feature

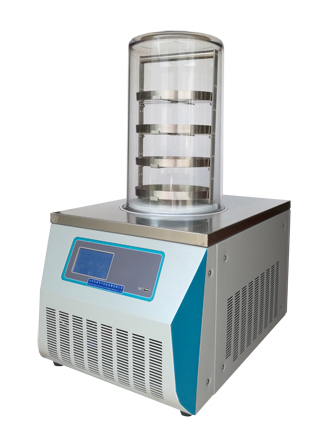

Integrated structure design, small size, no outer flange, easy to use, no leakage.

All materials in contact with the product are made of inert materials to meet GLP requirements.

The cold trap and operating table are made of stainless steel, which is corrosion-resistant and easy to clean.

All stainless steel gas (discharge) valve The company designs, produces, is safe, anti-corrosion, and does not leak.

The cold trap has a large opening, no inner coil, and has a sample pre-freezing function, without the need for a low-temperature refrigerator.

With professional air guiding technology, the cold trap catches ice uniformly and has a strong ice catching ability.

Internationally renowned brand compressors are highly efficient, energy-saving, long-life and low-noise.

The well-known brand vacuum pump has a fast pumping speed and can reach a higher ultimate vacuum.

The vacuum pump protection function can set the vacuum pump start-up cold trap temperature to protect the service life of the vacuum pump.

The professionally designed FD-LAB freeze dryer control system + SH-HPSC-I modular controller has high reliability and stability.

Intelligent data recording system, real-time record and display of cold trap temperature curve, sample temperature curve, vacuum curve, export data can be browsed and printed by computer.

Technical parameter

| Model | NBJ series vacuum freeze dryer | |||

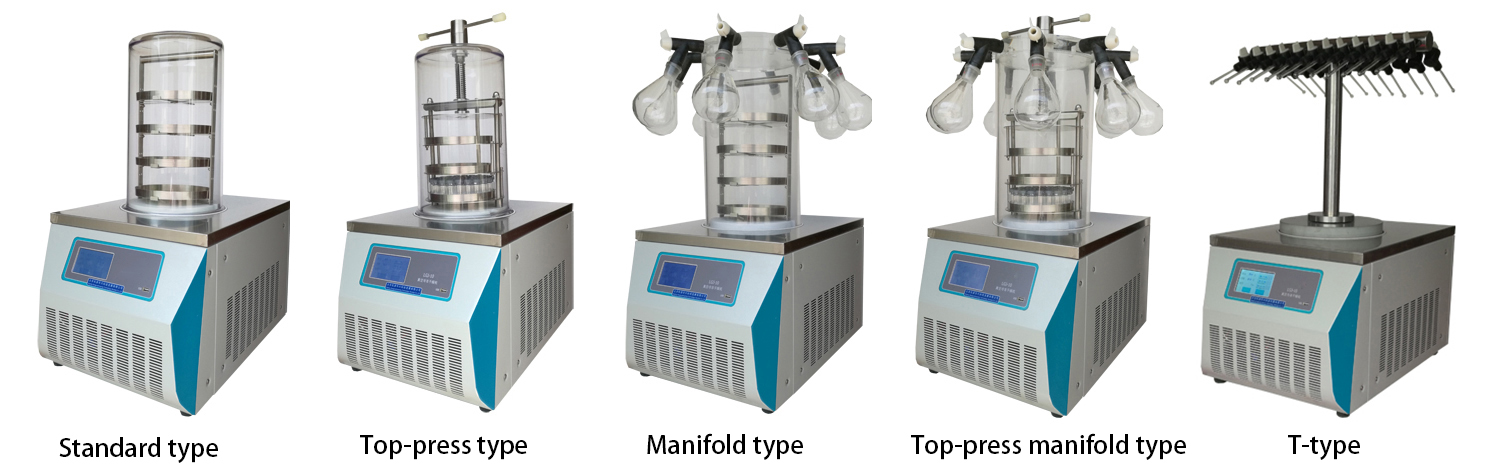

| Type | Standard | Standard manifold | Top-press | Top-press manifold |

| Freeze drying area | 0.12m2 | 0.08m2 | ||

| Material plate size | Ф200mm | Ф180mm | ||

| Model | NBJ series vacuum freeze dryer | |||

| Type | Standard | Standard manifold | Top-press | Top-press manifold |

| Freeze drying area | 0.12m2 | 0.08m2 | ||

| Material plate size | Ф200mm | Ф180mm | ||

| Number of material trays | 4 | 3 | ||

| Material disc spacing | 70mm | |||

| Cold trap temperature | ≤ -56 ° C (no load), optional ≤ -80 ° C (no load) | |||

| Cold trap depth | 140mm | |||

| Cold trap diameter | Ф215mm | |||

| Water catching capacity | 3-4kg/24h | |||

| Pumping rate | 2L/S | |||

| Ultimate vacuum | ≤ 5pa (no load) | |||

| Installed power | 970W | |||

| Host weight | 41kg | |||

| Mainframe dimensions | 615 × 450 × 370mm | |||

| -80 °C mainframe

dimensions |

850 × 680 × 405mm | |||

| Drying chamber size | Ф260×430mm | Ф260×465mm | Ф260×490mm | Ф260×540mm |

| Cooling method | air cooling | |||

| Defrost mode | naturalized cream | |||

| Panel material | 1.2L (material thickness

10mm) |

0.8L (material thickness

10mm) |

||

| Vials capacity | – | – | Ф12mm :492pcs | Ф12mm :492pcs |

| – | – | Ф16mm:279pcs | Ф16mm:279pcs | |

| – | – | Ф22mm:147pcs | Ф22mm:147pcs | |

Photo

Application difference

| Standard | Suitable for freeze drying of conventional materials in bulk (liquid, paste, solid) |

| Manifold | It is suitable for freeze-drying of bulk (liquid, paste, solid) conventional materials, and can be used to pick up the flask outside the drying chamber to dry the material that is frozen on the inner wall of the bottle. At this time, the flask is used as a container to be connected to the outside of the drying oven. On the tube, the material in the flask is heated at room temperature. Throughthe multi-manifold switch device, the flask can be removed or loaded at any time as needed without stopping the machine. |

| Top-press | It is not only suitable for the freeze-drying of conventional materials in bulk (liquid, paste, solid), but also suitable for the drying of the bottled materials of Xilin. When preparing for lyophilization, the materials are packed into the vials as needed, and the caps are floated and frozen. Drying, after the end of drying, the capping device is pressed tightly to avoid secondary pollution,re-adsorb moisture, and easy to store for a long time. |

| Top-press manifold | On the basis of the common type characteristics, it combines the characteristics of the gland type and the multi-tube type.Suitable for freeze drying of conventional materials in bulk (liquid, paste, solid);It is suitable for the drying of the bottled materials of vials. When preparing for lyophilization, the materials are packed into the vials as needed. After the caps are floated, the caps are freeze-dried. After the drying, the capping device is pressed to tighten the caps. Contamination, re-adsorption of water, easy to store for a long time; The flask is attached to the outside of the drying chamber, and the material frozen on the inner wall of the bottle is dried. At this time, the flask is connected as a container to the manifold outside the drying box, and the material in the flask is heated at room temperature through a multi-manifold switch device. The flask can be removed or loaded at any time as needed without downtime. |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Laboratory Freeze Dryer – 1L Laboratory Freeze Dryer – NANBEI , The product will supply to all over the world, such as: Brisbane, Plymouth, Serbia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.