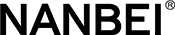

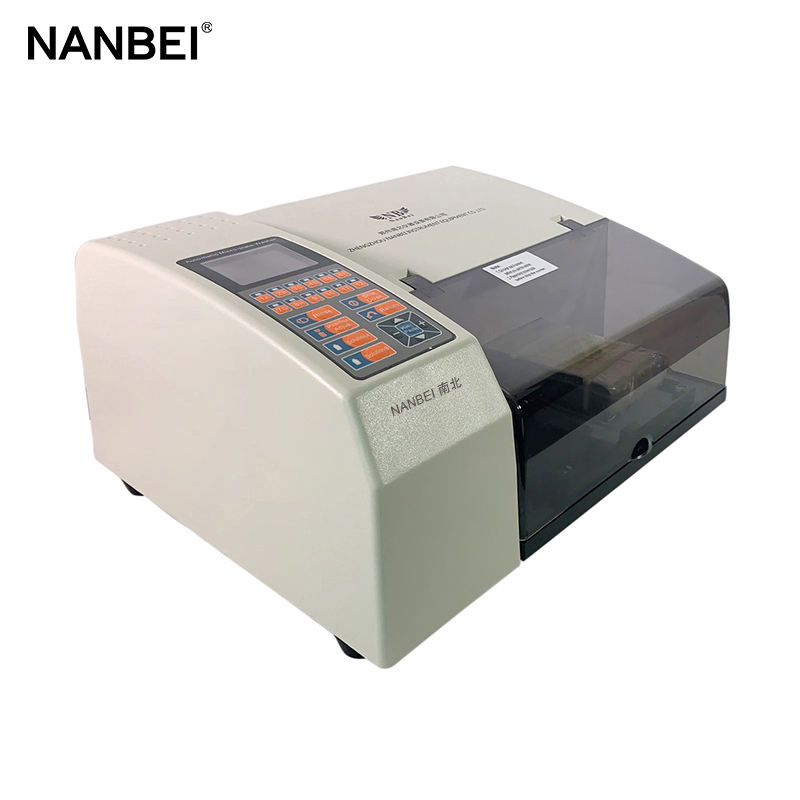

Micro-plate Washer

PW-960 full-Automatic Micro-plate Washer

Main Introduction

It is controlled by microcomputer to wash 48 well and 96 well microplate in experiments of Enzyme Linked Immunosorbent Assay (ELISA), Time-Resolved Immunofluorometric Assay (TRFIA) and Chemiluminescence, which are widely used in clinical diagnostic laboratories, centers for disease control and prevention, animal and plant quarantine, animal husbandry and veterinary epidemic prevention stations, biotechnological industries, food industries, environmental science, agricultural scientific research and other academic organizations.

Features

Efficiency ----2 Microplates alternative, washing 2 microplates within 1 minute.

Reliability ---- Special Washer manifolds design and anti-clogging technology can avoid cross-contamination and blocking.

Regulatory compliance ---- Meet the IVD-directive 98/79/EC for Europe, CE certified.

Convenience ---- Easy to maintain and operate.

Detailed features ---- Our profession makes it easy to use.

Uniform dispensing, low residual volume

Professional design of washer manifold’s interior double tanks can keep water pressure uniform. Dispense precision CV<1.5%.

Aspirating in multi-positions can guarantee low residual volume<0.7ul.

Two alternative microplate holders make speed double, which can make use of soaking time.

Washer manifolds work continuously, save time.

Professional anti-clogging technology

The control technology of pump pressure can avoid needle’s clogging.

Wash bottle filter can keep sediments in the solution away the pipes.

Pre-defined rinse procedure can avoid crystallizing in the pipes.

Detachable manifolds makes easy to clear particles in the manifolds.

Special cleaning fluid or pre-defined rinse procedure when turn on or turn off can make easy to maintain the device.

Avoid cross-contamination

Long needle for aspirating and short needle for dispensing make waste water and solution minimally contacted.

Soaking and shaking can avoid fluid’s adsorption.

Bottom holder is slope, in order that all waste water can flow along the surface and be pumped out, which can prevent microplates from contaminating.

Suitable to different sample’s quantity

Do not need to complement the whole plate or strip when any strip or hole is empty.

Do not need to stop working when change plates, which enhances productivity.

8-way or 12- way manifolds is available according to your conditions.

| Model | PW-960 |

| Wash head types | microplate 12 line×8 well and 8 line×12 well are available |

| Dispense uniformity | CV < 1.5% |

| Wash times | 1 to 99 times adjustable |

| Wash lines | whole plate or 1-12 lines random combination |

| Wash mode | Single plate, double plates or multi-plates |

| Dispensing volume | 50-950 μl, interval 50 μl adjustable

(May extend to 0-6000 μl interval 25 μl adjustable) |

| Wash speed | 5 seconds/plate, 140 plates /hour |

| Soaking time | 0 to 999 seconds adjustable |

| Shaking time | 0 to 999 seconds adjustable |

| Aspirating time | 0.1-99.9 seconds adjustable, interval 0.1second |

| Microplate positions | plate A and plate B |

| Residual volume | <0.7μl /well |

| Wash head positions adjustable | horizontal, left, right, middle, bottom, interval of plates |

| Bottle volume | 300ml and 4000 ml for solution bottle, 4000 ml for waste water bottle |

| Power Supply | 220V AC ± 30%,50Hz±3 Hz |

| External Dimensions | 53.8cm (21.2 in) × 42.6cm (16.8 in) × 23.0cm (9.1 in) (Height/width/depth) |

| Net Weight | 21kg |

| Note:

1. There are 3 kinds of devices: PW-960N, PW-960 and PW-960plus. 2. There is only one solution bottle for PW-960N. 3. PW-960 plus with added features: a) Auto discharge function for waste water. b) Water mist catching device keeps vacuum pump dry. 4. Solution bottle/waste water bottle: 300ml, 2000ml, 5000ml, 10L/ 20L |

|