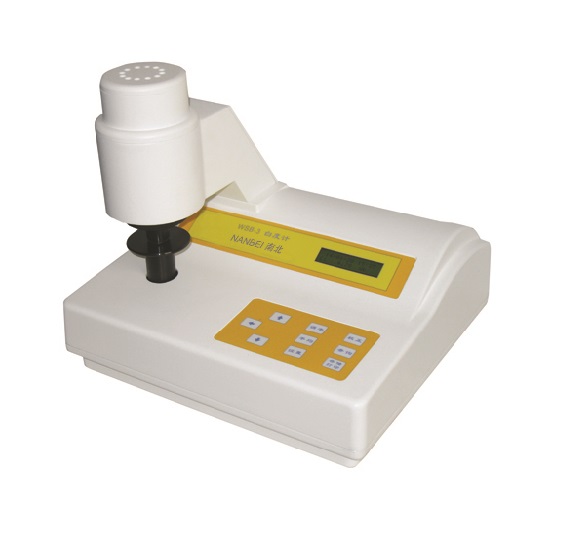

Whiteness tester, referred to as whiteness meter, is used to measure the blue light whiteness of the surface of objects. It is widely used in textiles, papermaking, printing and dyeing, ceramics, enamels, grains, plastics, building materials, paints, salt, chemicals and other production and commodity inspection departments that need to measure the whiteness of special items.

When using the whiteness meter, in order to ensure the standardization of testing, we should pay attention to the following aspects:

1. Before starting the machine, wipe the sample holder and measuring port of the instrument with cotton cloth or paper to avoid contaminating the whiteboard and test samples.

2. The surface of the test sample must be even and flat. When repeating the test, the consistency of the vertical and horizontal directions of the tested sample should be maintained.

3. To ensure the safety of operators, the equipment must be fully grounded when powered on.

4. Keep the surface of the working standard whiteboard and the reference standard whiteboard clean and avoid exposure to dust, so as not to artificially affect their nominal values.

5. After use, clean the sample box in time to avoid contamination of the container.

6. Cover the dust cover when not in use to ensure the cleanliness of the optical parts of the whiteness meter. If there is dust, use an ear-washing ball to blow off the surface dust or wipe it with lens paper, and do not touch it with your hands.

Post time: Feb-21-2022