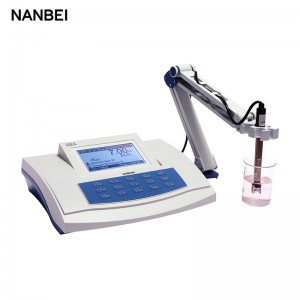

PH510T Portable pH Meter

证明书

The double-layer jacketed glass reactor is designed with double-layer glass. The inner layer can be filled with reaction solvent for stirring reaction, and the interlayer can be passed through different cold and heat sources (refrigerated liquid, hot water or hot oil) for cyclic heating or cooling reaction. Under the set constant temperature condition, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and it can be used for the reflux and distillation of the reaction solution. It is a modern fine chemical factory, biological pharmacy and Ideal pilot and production equipment for synthesis of new materials.

★ A full set of glassware with GG3.3 borosilicate glass production with good chemical and physical properties

★ Limit temperature of 250°C for high temperature experiments, and limit temperature of -60°C for low temperature experiments.

★ Titanium ring, new titanium alloy mechanical seal, sealing 0.098Mpa.

★ The PT100 temperature, and is a liquid crystal display. More accurate temperature measurement and more convenient.

★ Frequency control, AC induction motor. Constant speed, brushless, no spark, security and stability, and continuous work.

★ Quality 304 stainless steel all-inclusive PTFE stirring rod and a three-bladed propeller structure.

★ The bottom flanged discharge port with a Teflon value, aluminum parts flange fixed container no dead ends.

The double layer jacketed glass reactor has the main capacity of 1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 100L, 150L,200L, all of which have the function of lower discharge. More than 10 liters are equipped with universal casters for easy movement and The temperature display function in the kettle.

It can be used together with the vacuum pump to improve the working efficiency; the cooling coil of the glass condenser can be used together with the low temperature coolant circulating pump to improve the recycling efficiency. Please purchase the matching equipment at the discretion of the customer. The kettle body interlayer can be equipped with heating, refrigeration equipment or high and low temperature circulation devices according to the material reaction requirements.

| Model | NB-1 | NB-2 | NB-3 | NB-5 |

| Glass Material | GG-17 | GG-17 | GG-17 | GG-17 |

| Frame Material | 304 SUS | 304 SUS | 304 SUS | 304 SUS |

| Reaction bottle capacity | 1L | 2L | 3L | 5L |

| Jacketed Capacity | 0.4L | 0.5L | 0.6L | 0.8L |

| Flanged out of the oilcirculation port | Low feed high outlet | Low feed high outlet | Low feed high outlet | Low feed high outlet |

| Reaction bottle cover | 5 | 5 | 5 | 5 |

| Discharger port distanceto ground | 30mm | 30mm | 30mm | 30mm |

| Temp. range | -80-250℃ | -80-250℃ | -80-250℃ | -80-250℃ |

| Vacuum degreee | 0.098Mpa | 0.098Mpa | 0.098Mpa | 0.098Mpa |

| Stirring speed | 0-800rpm | 0-800rpm | 0-800rpm | 0-800rpm |

| Stirring diameter | 8mm | 8mm | 8mm | 8mm |

| Stirring power | 40W | 40W | 90W | 90W |

| Coltage(V/Hz) | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Dimension(mm) | 350*345*1000 | 350*345*1000 | 350*410*1250 | 350*410*1250 |

| Plate size(mm) | 325*345 | 325*345 | 325*410 | 325*410 |

| Packign size(mm) | 1200*480*400 | 1200*480*400 | 1380*500*400 | 1380*500*400 |

| Packign weight(KG) | 32 | 32 | 38 | 38 |