Vertical Planetary Ball Mill

Brief introduction of Laboratory ball mill :

Vertical planetary ball mill is a necessary device of high-tech materials mixing, fine grinding, sample making, new product development and small batch production. Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for R&D institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time). It gets powder samples under the vacuum state when equipped with vacuum ball mill tank.

Working Principle:

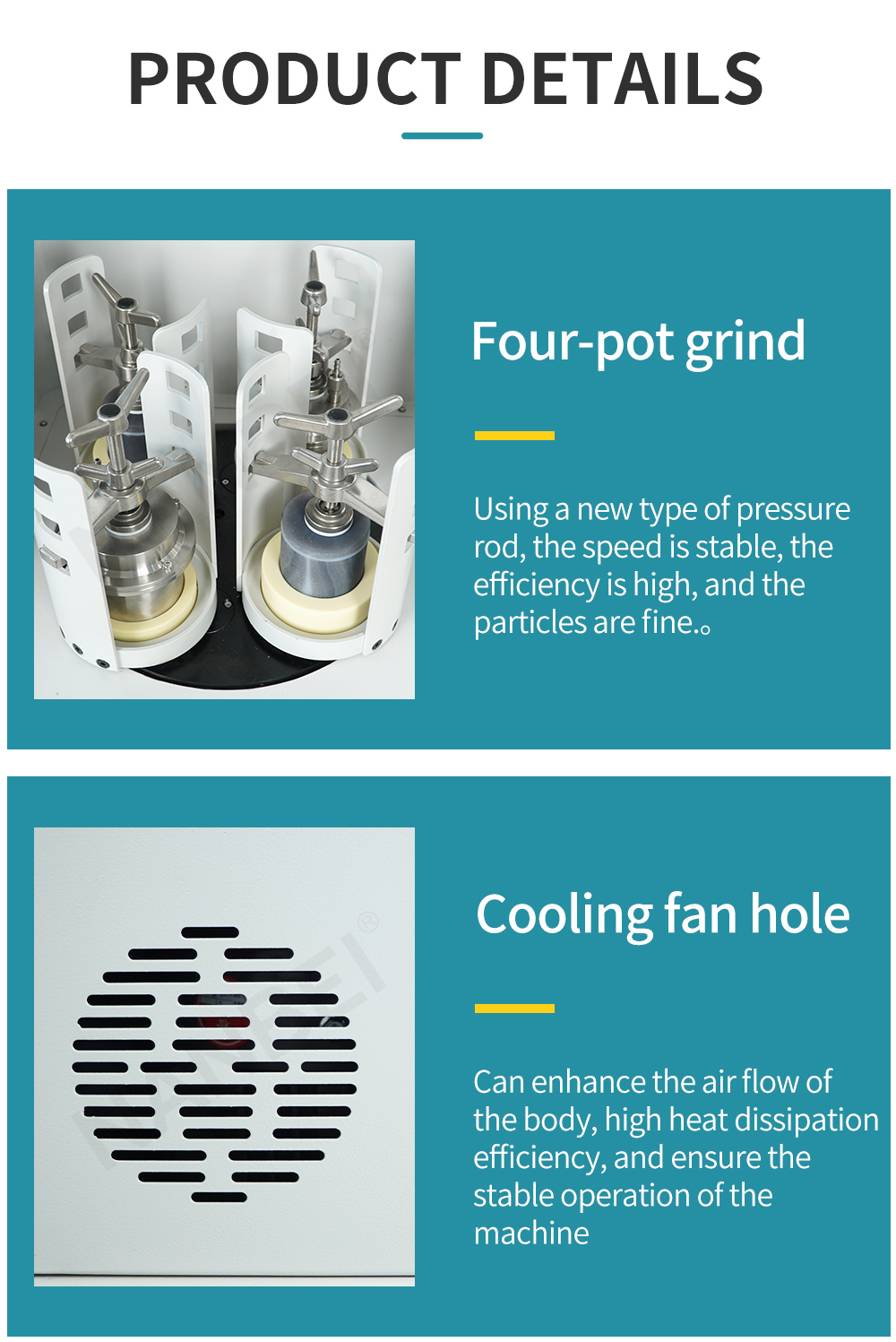

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method. Minimum granularity of ground powder can be as small as 0.1um.

Features of Laboratory ball mill:

1.Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

2. Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small Granularity.

3. Four powder samples from different sizes and different materials can be produced at one time.

4. The machine is controlled by frequency converter, you may choose ideal rotating speed according to expected experimental result. The converter is equipped with device of under voltage and over-current to protect the motor.

5. The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, time setting according to experimental needs, so as to improve efficiency of grinding.

6. Technical features of Tencan Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss.

7. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running

Grinding jars and ball:

Besides the planetary ball mill machine, our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

|

Drive mode |

Gear drive and belt drive |

||||

|

Operate Mode |

2 or 4 grinding jars work together |

||||

|

Max loading capacity |

2/3 capacity of jar |

||||

|

Feeding size |

Soil≤10mm;Others≤10mm |

||||

|

Output size |

More than 0.1um |

||||

|

Rotation speed ratio |

1:2 |

||||

|

Speed control |

Frequency control |

||||

|

Technical Parameter Table(I) of Vertical Square Planetary Ball Mill (Production Type) |

|||||

|

Type NO |

Specification |

Volume of Each Matched Pot |

Quantity |

Remarks |

|

|

NXQM-20 |

20L |

2-5L |

4pcs |

Matched with vacuum mill pots from 2L to 4L |

|

|

NXQM-40 |

40L |

5-10L |

4pcs |

Can be Matched with 5L Vacuum mill Pot |

|

|

NXQM-60 |

60L |

10-15L |

4pcs |

Can be Matched with 10L Vacuum mill Pot |

|

|

NXQM-100 |

100L |

20-25L |

4pcs |

Can be Matched with 20L Vacuum mill Pot |

|

|

Technical Parameter Table(II) of Vertical Square Planetary Ball Mill (Production Type) |

|||||||

|

Model |

Power |

Voltage |

Revolution |

Rotation |

Total |

Alternating Run Time |

Noise≤db |

|

NXQM-20 |

4 |

380V-50Hz |

25-215 |

50-430 |

1-9999 |

1-999 |

65db |

|

NXQM-40 |

5.5 |

380V-50Hz |

20-195 |

40-390 |

1-9999 |

1-999 |

68db |

|

NXQM-60 |

7.5 |

380V-50Hz |

27-174 |

40-260 |

1-9999 |

1-999 |

68db |

|

NXQM-100 |

11 |

380V-50Hz |

27-160 |

40-240 |

1-9999 |

1-999 |

68db |