X-Ray Fluorescence spectrometer

Quality and Technical Supervision Bureau (Environmental Directive)

RoHS/Rohs (China)/ELF/EN71

Toy

Paper, ceramics, paint, metal, etc.

Electrical and electronic materials

Semiconductors, magnetic materials, solder, electronic parts, etc.

Steel, non-ferrous metals

Alloys, precious metals, slag, ore, etc.

chemical industry

Mineral products, chemical fibers, catalysts, coatings, paints, cosmetics, etc.

environment

Soil, food, industrial waste, coal powder

Oil

Oil, lubricating oil, heavy oil, polymer, etc.

other

Coating thickness measurement, coal, archaeology, material research and forensics, etc..

● Three different types of X-ray radiation safety systems, software interlocks,hardware interlocks, and mechanical interlocks, will completely eliminate radiation leakage under any working condition.

● The XD-8010 features a uniquely designed optical path that minimizes distances between the X-ray source, sample, and detector while maintaining the flexibility to switch between a variety of filters and collimators. This significantly improves the sensitivity, and lowers the detection limit.

● The large volume sample chamber allows large samples to be directly analyzed without the need for damage or pre-treatment.

● Simple, one-button analysis using a convenient and intuitive software interface. Professional training is not required to perform basic operation of the instrument.

● The XD-8010 provides rapid elemental analysis of elements from S to U, with adjustable analysis times.

● Up to 15 combinations of filters and collimators. Filters of various thicknesses and materials are available, as well as collimators ranging from Φ1 mm to Φ7 mm.

● The powerful report formatting feature allows for flexible customization of the automatically generated analysis reports. The generated reports can be saved in PDF and Excel formats. The analysis data is automatically stored after each analysis.Historical data and statistics can be accessed at any time from a simple query interface.

● Using the instrument's sample camera, you can observe the position of the sample relative to the focus of the X-ray source. Pictures of the sample are taken when analysis begins and can be displayed in the analysis report.

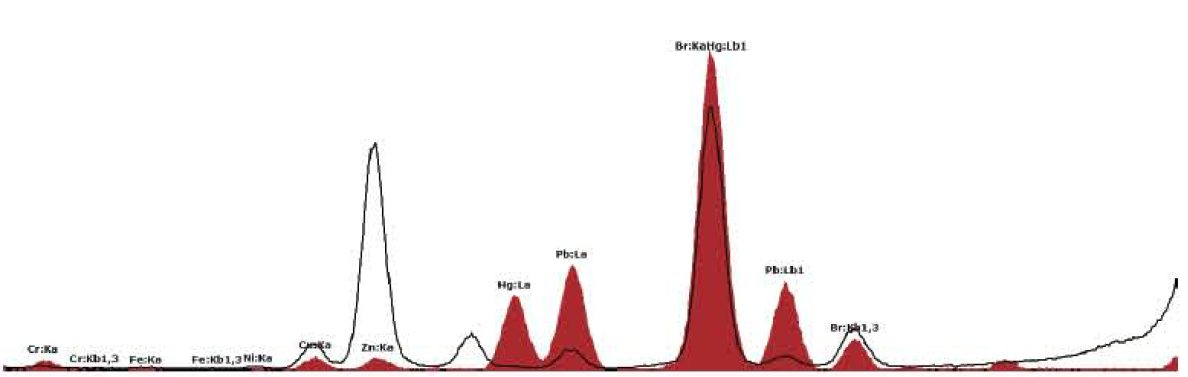

● The software's spectra comparison tool is useful for qualitative analysis and material identification and comparison.

● By using proven and effective methods of qualitative and quantitative analysis, the accuracy of the results can be assured.

● The open and flexible calibration curve fitting feature is useful for a variety of applications such as the detection of harmful substances.

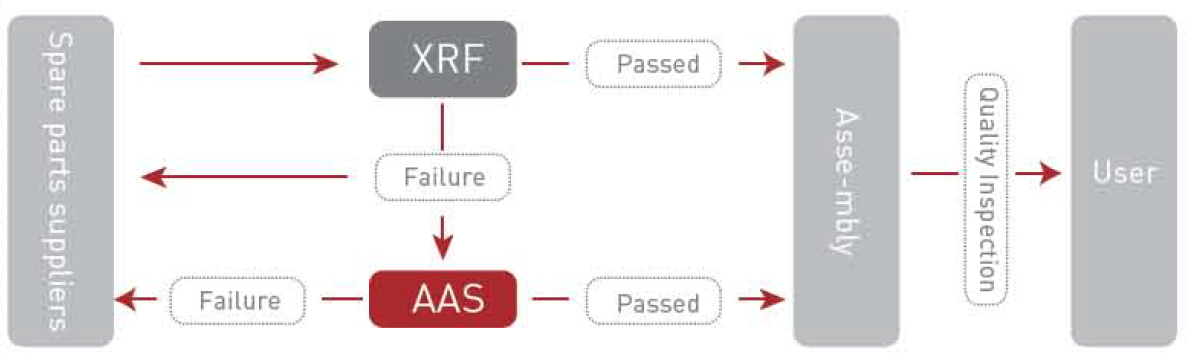

Harmful element analysis method

| Hazardous Substances | Example | |

| Screening Analysis | Detailed analysis | |

| Hg | X-ray spectroscopy | AAS |

| Pb | ||

| Cd | ||

| Cr6+ | X-ray spectroscopy(Analysis of total Cr) | Ion chromatography |

| PBBs / PBDEs | X-ray spectroscopy(Analysis of total Br) | GC-MS |

Quality Management Process

Measurement of harmful trace element in polyethylene samples, such as Cr, Br, Cd, Hg and Pb.

• The difference of given values and the actual values of Cr, Br, Cd, Hg and Pb.

The difference of given values and the actual values of Cr, (Unit: ppm)

| Sample | Given Value | Actual Value (XD-8010) |

| Blank | 0 | 0 |

| Sample 1 | 97.3 | 97.4 |

| Sample 2 | 288 | 309.8 |

| Sample 3 | 1122 | 1107.6 |

The difference of given values and the actual values of Br, (Unit: ppm)

| Sample | Given Value | Actual Value (XD-8010) |

| Blank | 0 | 0 |

| Sample 1 | 90 | 89.7 |

| Sample 2 | 280 | 281.3 |

| Sample 3 | 1116 | 1114.1 |

The difference of given values and the actual values of Cd, (Unit: ppm)

| Sample | Given Value | Actual Value (XD-8010) |

| Blank | 0 | 0 |

| Sample 1 | 8.7 | 9.8 |

| Sample 2 | 26.7 | 23.8 |

| Sample 3 | 107 | 107.5 |

The difference of given values and the actual values og Hg, (Unit: ppm)

| Sample | Given Value | Actual Value (XD-8010) |

| Blank | 0 | 0 |

| Sample 1 | 91.5 | 87.5 |

| Sample 2 | 271 | 283.5 |

| Sample 3 | 1096 | 1089.5 |

The difference of given values and the actual values of Pb, (Unit: ppm)

| Sample | Given Value | Actual Value (XD-8010) |

| Blank | 0 | 0 |

| Sample 1 | 93.1 | 91.4 |

| Sample 2 | 276 | 283.9 |

| Sample 3 | 1122 | 1120.3 |

The repeated measurement data of sample 3 Cr1122ppm, Br116ppm, Cd10ppm, Hg1096ppm, Pb1122ppm (Unit: ppm)

| Cr | Br | Cd | Hg | Pb | |

| 1 | 1128.7 | 1118.9 | 110.4 | 1079.5 | 1109.4 |

| 2 | 1126.2 | 1119.5 | 110.8 | 1072.4 | 1131.8 |

| 3 | 1111.5 | 1115.5 | 115.8 | 1068.9 | 1099.5 |

| 4 | 1122.1 | 1119.9 | 110.3 | 1086.0 | 1103.0 |

| 5 | 1115.6 | 1123.6 | 103.9 | 1080.7 | 1114.8 |

| 6 | 1136.6 | 1113.2 | 101.2 | 1068.8 | 1103.6 |

| 7 | 1129.5 | 1112.4 | 105.3 | 1079.0 | 1108.0 |

| Average | 1124.3 | 1117.6 | 108.2 | 1076.5 | 1110.0 |

| Standard deviation | 8.61 | 4.03 | 4.99 | 6.54 | 10.82 |

| RSD | 0.77% | 0.36% | 4.62% | 0.61% | 0.98% |

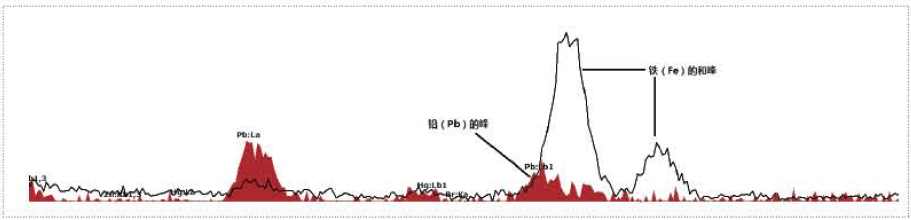

Secondary filter for Pb element (Steel substrate samples), Sample: Steel (Pb 113ppm)

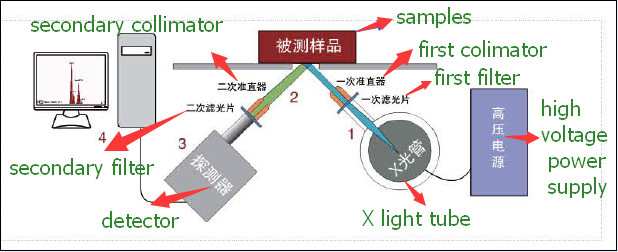

1.X-ray radiation from the primary X-ray tube, is irradiated through a collimator to the sample.

2.Primary X-ray excitation characteristics of the elements contained in the sample X-rays through the secondary collimator into the detector

3.Processed through the detector, forming fluorescence spectroscopy data

4.Computer spectroscopy data analysis, qualitative and quantitative analysis is completed

| Model | NB-8010 | |

| Analysis principle |

Energy dispersive X-ray fluorescence analysis |

|

| Elements Range | S (16) |

|

| Sample | Plastic / metal / film / solid / liquid / powder, etc., any size and irregular shape |

|

| X - ray tube | Target | Mo |

| Tube voltage | (5-50)kV | |

| Tube current | (10-1000)uA | |

| Sample irradiation diameter |

F1mm-F7mm | |

| Filter | 15 sets of composite filter is automatically selected, and the automatic conversion |

|

| Detector | Imports from the United States Si-PIN detector |

|

| The data processing circuit board |

Imports from the United States, with the use of Si-PIN detector sets |

|

| Sample observation |

With 300,000-pixel CCD camera | |

| The sample chamber size |

490 (L)´430 (W)´150 (H) | |

| Analysis method | Linear linear, quadratic Code lines, strength and concentration calibration correction |

|

| Operating system software |

Windows XP, Windows7 | |

| Data management | Excel data management, test reports, PDF / Excel format saved |

|

| Working environment |

Temperature: £30°C. Humidity£70% | |

| Weight | 55kg | |

| Dimensions | 550´450´395 | |

| Power supply | AC220V±10%,50/60Hz | |

| Determination conditions |

Atmospheric environment | |